RESISTRON

2019-05-14 17:25

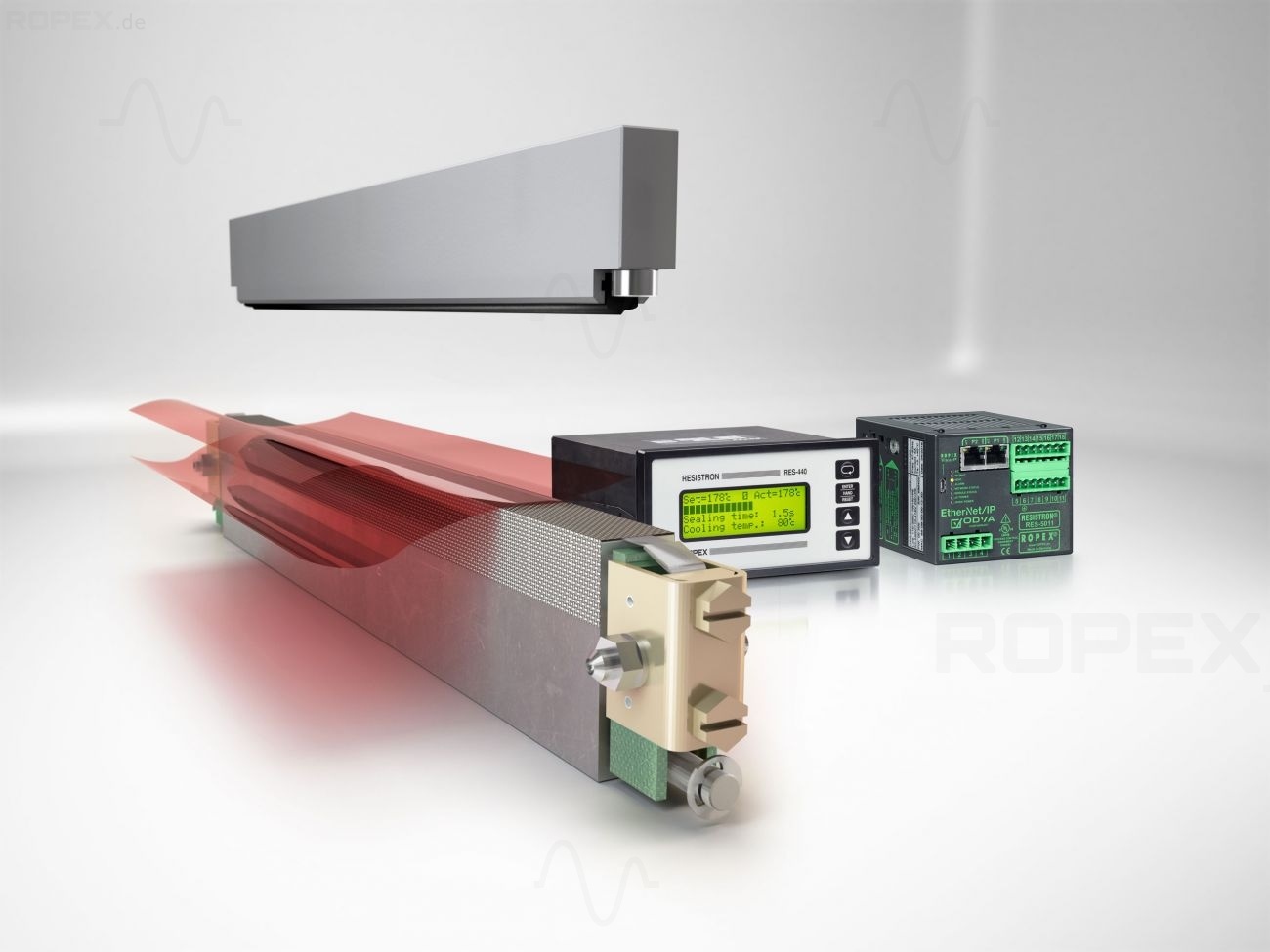

RESISTRON thermoplastic film pulse sealing system.

Modern packaging must meet higher and higher quality and visual requirements. The faster cycle rate must be coordinated with the thinner and therefore more sensitive film types used today. This makes it more difficult to ensure a repeatable sealing process.

The "RESISTRON sealing system" developed by ROPEX is a complete system configuration consisting of several application-specific components. The two most important of these components are the RES temperature controller and the RES sealing tool. The RES sealing tool is a heat seal with a heat seal band and a matching counter bar, which can be customized according to your personal sealing application. By combining it with system components, you can obtain customized system configuration.

Pulse sealing with heat sealing tape

The heat sealing tape is basically a thin metal strip or wire made of special resistance alloy, which must meet some physical requirements. These strips are shaped, shaped and coated according to the application. The heat sealing tape performs dual functions in the RESISTRON environment. When power is supplied, it acts as the heat source of the sealing process. At the same time, as a temperature sensor, it changes its resistance as the temperature increases. The ability of the RES temperature controller to quickly measure resistance changes during the heating and cooling phases is critical to this high dynamic and sensorless control concept. This explains the strict specification defined for heat sealing alloy. The most important characteristics of heat sealing tape are:

- Temperature coefficient of resistance

- Specific resistance

- Expansionary behavior

These characteristics and the application of heat sealing have a decisive impact on the specification of electrical components and the mechanical structure of sealing strips. The whole system is obviously very complex, and all system components need to interact with each other optimally. Our suggestion to you is to let our support team calculate your heat sealing application. Then you can organize a complete system for you, including all necessary components and settings.

Operating principle of RESISTRON temperature controller

In order to obtain the best application, the value of each parameter must be determined, and the sequence of steps is suitable for the thermal sealing task. Regardless of the operating conditions of the production machine, observing these parameters is a key challenge for the RESISTRON temperature controller.

In order to accurately determine and control the temperature of heat sealing tape, extremely accurate and fast measurement is essential. In the heat sealing system with RESISTRON temperature controller, it can be realized without sensor by measuring the voltage and current at the heat sealing belt. Repeat the measurement 50 or 60 times per second. The ACTUAL temperature can then be calculated from the voltage and current values using the resistance characteristics of the heat seal tape. Then compare it with SET temperature and correct it when the difference is not zero. This is accomplished by changing the transformer voltage until ACT=SET. Even very low heat loads can be detected immediately and can be corrected quickly and accurately. The power controller on the primary side of the transformer acts as an actuator.

Because the controlled primary current is much lower and the heat loss is smaller, it paves the way for the design of compact controller that users attach so much importance to.

Heat seal with heat seal

The heat sealing strip used as the substructure of the heat sealing strip is usually made of aluminum. It contains all the necessary design elements so that the band can complete the work reliably, such as:

- Rod end block can compensate for expansion

- Electrical connection of large current and measuring cables

- Fixed heat sealing tape

- Coolant hole (if required)

The most popular design of insulating layer used for heat sealing tape is straight sealing strip, with rectangular section and length ranging from several centimeters to several meters. The profile seal can provide 2D profiles (such as round, angular or curved) and 3D profiles for sealing tubes or nozzles.

Specific design rules are applicable to this tool, and high accuracy is crucial for achieving uniform temperature distribution. Our developers use the advanced CAD system to create the 3D view of the thermal seal. The CAD file can then be sent to the customer, who will integrate it into the company's own CAD environment.

Heat sealing tape

As has been mentioned elsewhere, the heat sealing belt is the main part of the sealing process, which is why special attention should be paid to the precise geometric shape, the contour suitable for the process and the passive area of copper or silver plating. Of course, the electrical characteristics of the heat-bonded strip alloy, such as specific resistance and temperature characteristics, must be observed.

The best matching heat sealing belt with the substructure is crucial to the success of the pulse sealing system. The heat sealing belt designed by us can be customized according to your requirements, and can also design matching substructure according to your requirements.

Customized solutions

Is your application unusual? Does it need customized solutions? If so, you have come to the right place! ROPEX has long experience in the development of pulse sealing and heat sealing applications, which enables us to provide relevant answers no matter how unique the problem is.

We have designed a heat seal and belt that meet your requirements, and accurately combined the sealing system you are looking for. We can also use your actual film to conduct sealing test in our test laboratory and quantify the results. Then, we will provide you with a detailed application report, including all relevant components, parameters required for the sealing process and any necessary technical drawings of mechanical components.

system configuration

The RESISTRON sealing system is composed of several specific application components, among which the temperature controller, pulse transformer and thermal seal are the three most important components in the thermal seal application. Various other system components are also required, such as current filter, current transformer and counter bar. The combination of all these components adds to your personal heat sealing system.

Our support team can help you configure your application and integrate it into the machine and process chain. The application report prepared by ROPEX for you constitutes the starting point of all RESISTRON sealing systems in the machine.

Related News

Address: 607, Environmental Protection Building, 2003

Dongxiao Road, Luohu District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanical Technology Co., Ltd

Message