CIRUS

2019-05-14 17:34

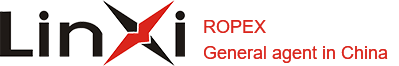

CIRUS is used for heat sealing system of thermoplastic film.

For machines with high product output, special packaging applications or packaging commodity requirements, film materials are selected under the pressure of installation cost - all these factors lead to film types posing a serious challenge to the sealing system.

Therefore, users are increasingly turning their attention to issues such as joint quality and consistent repeatability, the shortest sealing time and the minimum thermal stress on the packaging items - not to mention the requirements for less downtime due to maintenance, replacement of vulnerable parts or replacement of devices. ROPEX is the ideal solution to solve these problems: CIRUS series sealing system and related supplementary components.

Perfect solution

ROPEX CIRUS (metal ceramic integrated resistance type ultra-high speed sensorless) heat sealing system is an ideal solution for heat sealing applications: whenever high temperature dynamic is required to heat and cool sealing tools, sealing seams or bags are complex, and it is an ideal choice for the contour and no - or only minimal - thermal stress of the packaging goods. In addition, the CIRUS sealing tool requires little maintenance because - unlike traditional pulse sealing strips - it has no moving parts, such as rod end blocks, which may break or get stuck to compensate for the linear thermal expansion of the metal strip. CIRUS technology also eliminates product replacement time because it can handle different film widths without changing the length of the active heating tool (in other words, the tool works independently of a specific format).

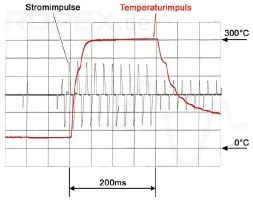

Heat up and cool down in a few milliseconds

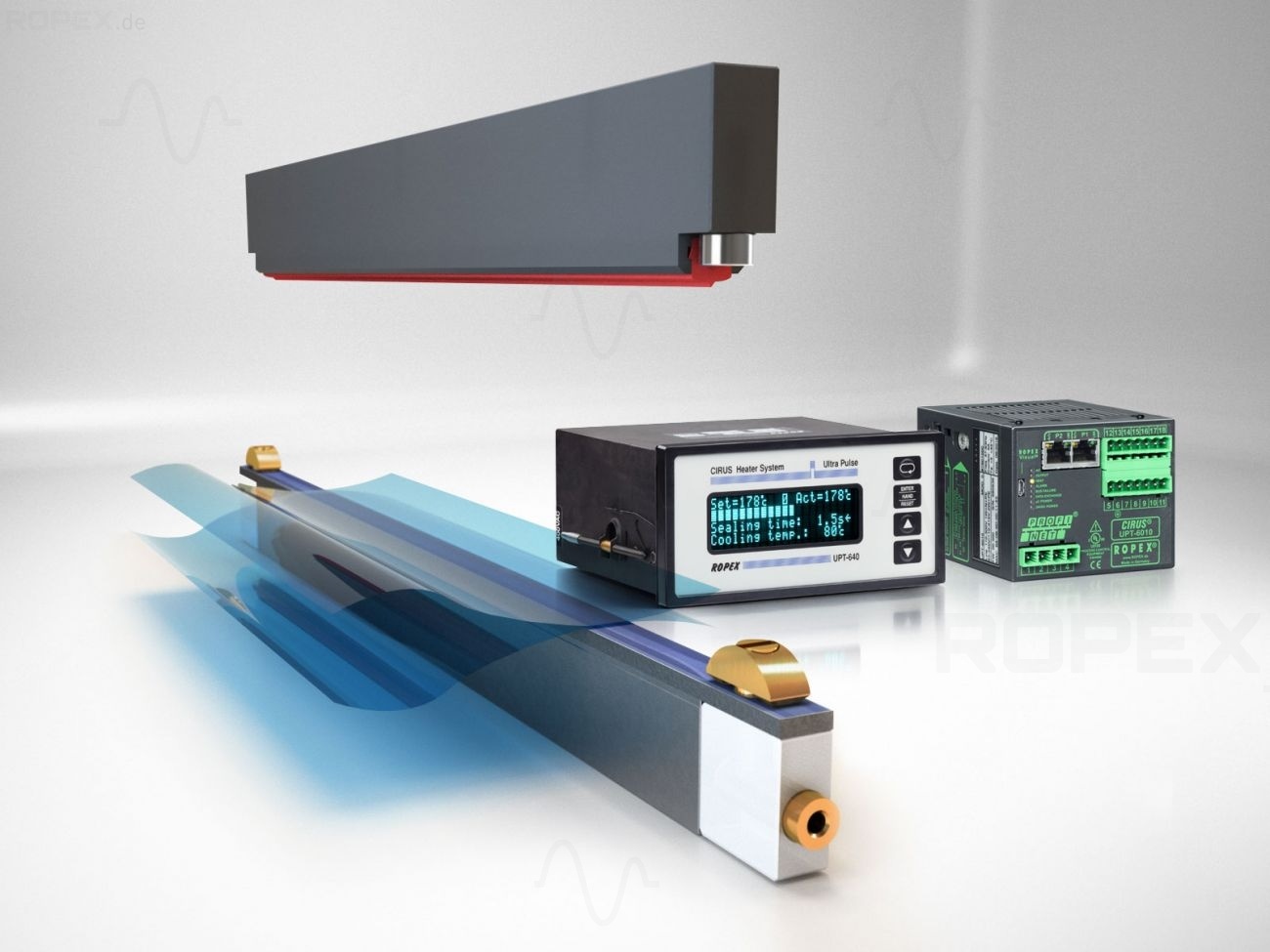

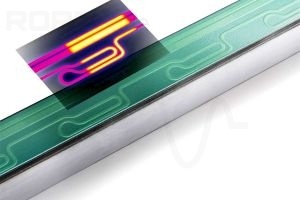

The extremely high temperature dynamic of our CIRUS tool is the result of its special structure: before taking the actual heating wire as the power resistance, several insulating layers are printed on the flat stainless steel pad in the screen process. In addition, the electrical insulation layer is combined to insulate the tool and protect the resistance layer from external influences. Each printing layer is burned by sintering, so as to form a solid bond between each layer and the bottom layer. Then the thermal sealing element obtained in this way is fused to the stainless steel cooling substructure, which has an integrated channel for water flow.

Heating impulse

Compared with the traditional heat sealing system, this special tool design has novel features: for example, because the heating line is only a few microns thick and the heat capacity is also very low, it can achieve extremely high temperature dynamic, namely 6000 K/s.

Transmit heat

The heat transfer between the film and the integrated water cooling unit is very good because the printing layer is very thin. Therefore, the sealing joint cools very quickly and effectively. Compared with the traditional heat sealing method, the combination of CIRUS tool's extremely high temperature dynamic and water cooling system can ultimately significantly shorten the process time and improve productivity. Due to the special tool structure, the thermal expansion caused by the temperature rise in the heating line and the gasket is reduced, so the CIRUS thermal seal does not need mechanical parts to compensate for this effect. Therefore, broken springs or stuck rod end blocks are eliminated, which may be the problem of metal thermal sealing elements.

Outline of each heating line

If the standard UPT sealing strip is not suitable for the task at hand, you can clearly make customized tools according to your application. In this case, according to your detailed specifications, work closely with customers to design and manufacture heat sealing tools. Due to the special production technology used for heat sealing components, the heating line profile can be customized according to personal requirements. Curved seal geometries are also possible, such as round or oval. Overlapping temperature curves can also be achieved.

system configuration

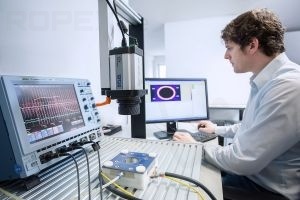

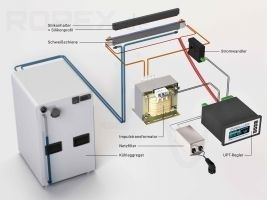

In addition to actual sealing tools, CIRUS sealing system also includes a temperature controller and various complementary components, such as current filter, pulse transformer, current transformer and counter rod. The cooling device is another important part of the system. The electrical and thermal design of the integrated system is the responsibility of ROPEX. You can always get a complete system that can be used in your application at any time: by observing our technical suggestions, you can benefit from the optimization function of the technology, thus minimizing the workload of installation, startup and maintenance.

Prev:

Next:

Related News

Address: 607, Environmental Protection Building, 2003

Dongxiao Road, Luohu District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanical Technology Co., Ltd

Message